The custom fabrication thread! (Post pics of stuff you have made)

#604

Don't shoot me but i am going water to air IC, a similar setup that i used on my M45 1.6 w AC and PS if it can keep intake charge cool on that 1.6 @ 8k it will do just fine on this much more efficient turbo setup.

I moved tha AC condencer 2" fwd and installed the oem radiator w u channel caps in its place for cooling the water and going w a koyo and sumitomo fans.

I moved tha AC condencer 2" fwd and installed the oem radiator w u channel caps in its place for cooling the water and going w a koyo and sumitomo fans.

#606

I made a crude fixture with a head and turbo flange that positions each at the correct location relative to each other and then bolted the actual manifold flanges to it and build it from there, i would use 1-1/4 sch 40 but weld fittings insread of the 1-1/2 i used if i was to do it again, it will make the manifold more compact for a better fit and keep higher exhaust velocity most likley improoving spool; i am considering buildimg another one just for those reasons.

#607

I made a crude fixture with a head and turbo flange that positions each at the correct location relative to each other and then bolted the actual manifold flanges to it and build it from there, i would use 1-1/4 sch 40 but weld fittings insread of the 1-1/2 i used if i was to do it again, it will make the manifold more compact for a better fit and keep higher exhaust velocity most likley improoving spool; i am considering buildimg another one just for those reasons.

#608

I don't have SW and have been asking my boss to let me purchase a seat, for the time being i purchased Inventor LT suite on my own so i can draw parts and get by for the time being, one great trick i started using is a line laser from a small bench top drill that i use for marking the parts before cutting them, that saved a lot of fitting and sanding.

#610

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

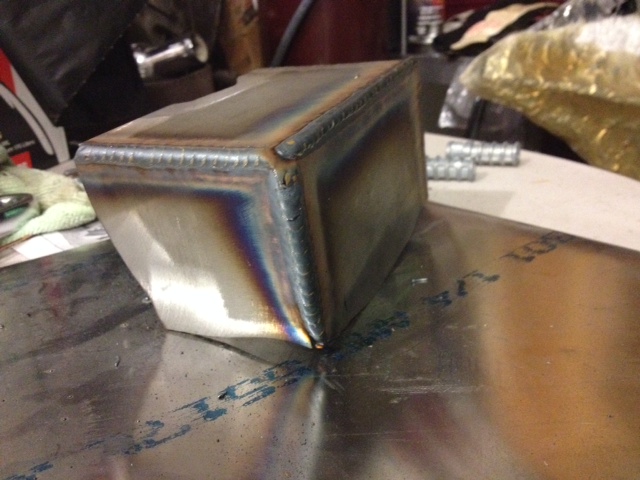

Start of a top mount BP turbo manifold for a CRAZY NB.

4-1 TiAL Vband Collector by HellaFab, on Flickr

4-1 TiAL Vband Collector by HellaFab, on Flickr